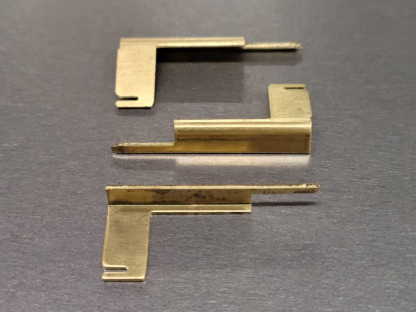

This product was designed for use as an electrical terminal, which is used in a vehicle’s fluid level sensor. It is formed from 0.032" thick 70/30 ½ hard brass, and exemplifies our ability to manufacture high volume precision components.

The coil stock had to be bent, slotted, formed, and cutout using a progressive die; this is done on our 80 ton STAMTEC gap press which is able to achieve the required tolerances of ±0.002". After deburring, inspections are performed utilizing various measuring equipment to ensure quality and uniformity. We produce approximately 300,000 of these terminals per year for our customer in Georgia, with a lead time of 3-4 weeks per order.